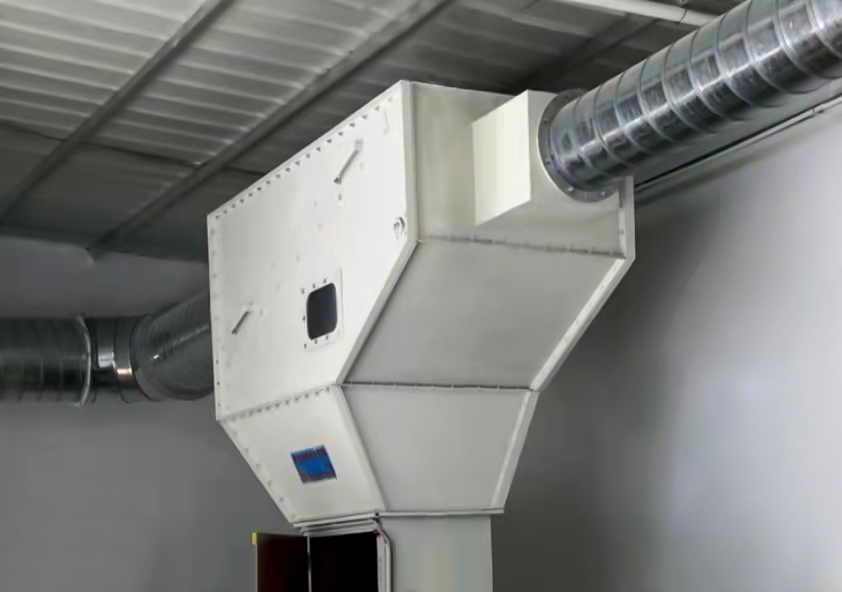

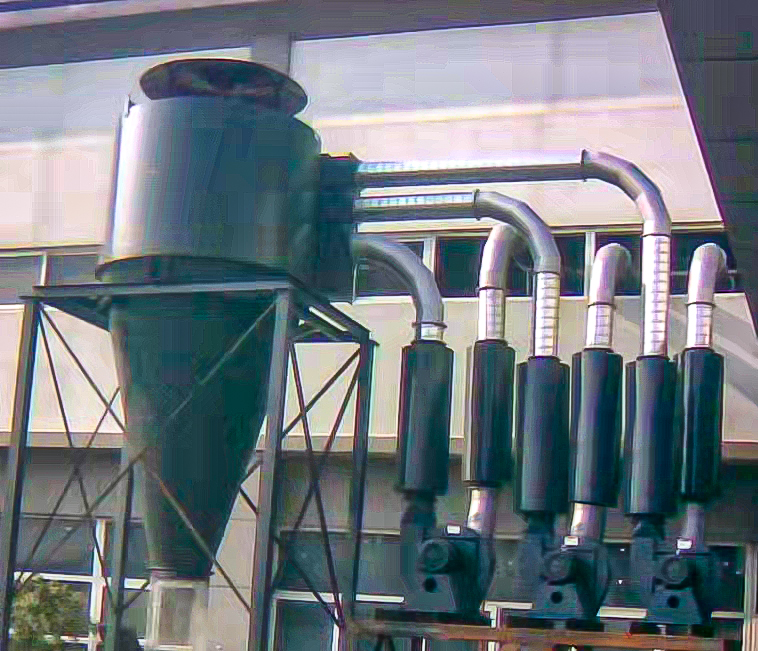

To separate air and waste paper dust from high-pressure mixtures, two types of air separators can be used: rotary material separators and cyclone separators. The inlet of the air separator is usually connected with the outlet of the rectifier fan. Under normal circumstances, the air discharged by the rotating material separator still contains a large amount of paper dust, so it needs to be filtered by the pulse spray bag filter before discharge. The filtered air particles can reach the level of PM2.0. The air discharged from the cyclone contains less paper dust than the air discharged from the pulse-jet filter. If the discharge standard is not too strict, the air discharged from the cyclone can be directly discharged.