Corrugated Conveyor Systems Customized Service

|

|

Whatever in the way, our designers can handle Our Advantages. |

| Reduce Bottom Sheets Breakage Solutions |

|

|

Ideal choice to reduce bottom sheets waste. Application scope: The board dispenser is connected with conveyor on the stacking station of the corrugated cardboard production line, which is used for automatically placing base board before conveying cardboard stack. This avoids damage to the bottom of the stack, and provides protection of bottom edge, thus less waste generated. Advantages.

|

| Corrugator Discharge Solutions |

|

|

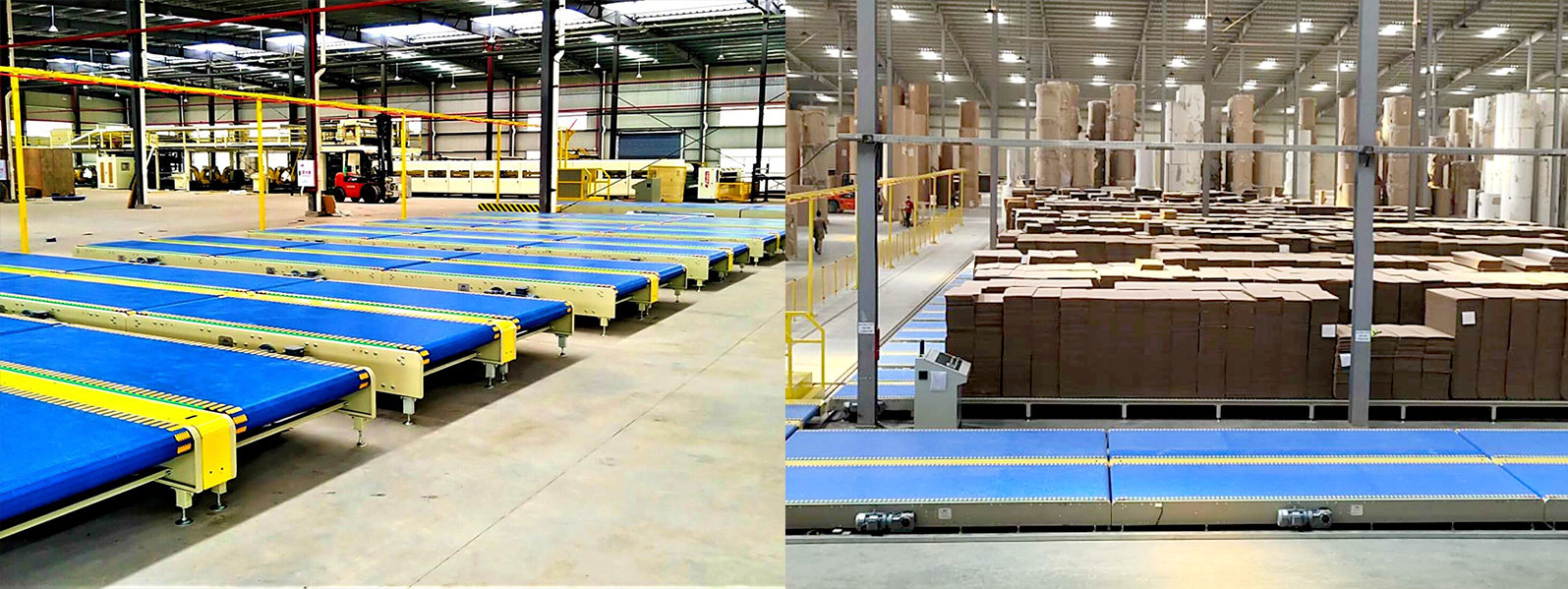

Plastic chain conveyors for corrugator discharge The handling system receives the production data form the corrugator and from the planning system, in order to prepare the loading units, and to move them, the full-surface plastic conveyors ensure the fast and gentle discharge of all stack qualities from the stacker of the corrugator. up to the converting machines. Advantages.

|

| Transfer Stack of Sheets Solutions |

|

|||||

|

Traffic-jam-free work-in-progress storage with great efficiency High-performance transfer cart offers excessive extra efficiency for your work-in-progress storage . With maximum speed up to 120m/min and laser rangefinders equipped, the cart can transport the stacks precisely to where they are needed. Safety is another point to emphasis here – the cart equips two laser scanners each on the front sides, with which a controller is designed so that manual operation is supported as well. Corrugated conveyor systems employs corrugated conveyors and RGVs (Rail Guided Vehicle) to handle transportations of corrugated cardboards between processes of production and storage in a high effiency manner. Configurations of control system is customizable to fit certain situations, and realize the optimal automated intralogistics efficiency. Advantages.

|

|||||

|

WIP Handling Solutions |

|||||

|

|||||

|

Stack transportation is stable and uninterrupted Stack transportation is proceeded with our tested conveyor. The Cardboard conveyor system equips modular plastic chains made of acetal to achieve high stability and efficiency. Advantages

|

Customized Conveyor